MedlonUploaded:2024-09-21Browse:206

In the fast-evolving world of electronics and power management, manufacturers like Medlon are at the forefront of delivering reliable, efficient, and high-quality power blade connectors. When it comes to determining pricing for these products, quality control plays a pivotal role. By maintaining stringent quality checks throughout the manufacturing process, Medlon ensures that its power blade connectors meet industry standards, offer durability, and provide optimal performance in various applications. But how exactly does quality control influence the pricing of these essential components?

Quality control is the foundation of any manufacturing process, particularly in the production of power connectors, where even minor defects can lead to product failure. At Medlon, every stage of production is closely monitored to ensure that each power blade connector is produced without compromise. From the raw materials to the final product, comprehensive testing and inspections are conducted. This rigorous quality assurance not only guarantees product reliability but also affects the overall pricing structure.

Power blade connectors must withstand high voltages, resist heat, and provide secure connections over long periods. Ensuring these characteristics means using high-quality materials and following precise manufacturing processes. As a result, the cost of these components reflects the level of care, testing, and certification that goes into producing a product that is both safe and durable. By investing in quality control, Medlon reduces the risk of recalls, warranty claims, and product malfunctions, saving customers money in the long run.

Medlon's power blade connectors are engineered to deliver consistent and dependable performance in demanding environments. These connectors are designed with robust features, such as high-conductivity contacts and secure locking mechanisms, ensuring a reliable connection even under heavy electrical loads. Additionally, the materials used in production are chosen for their ability to resist corrosion, minimize electrical resistance, and enhance heat dissipation. By prioritizing these features, Medlon ensures its power connectors perform at the highest standards.

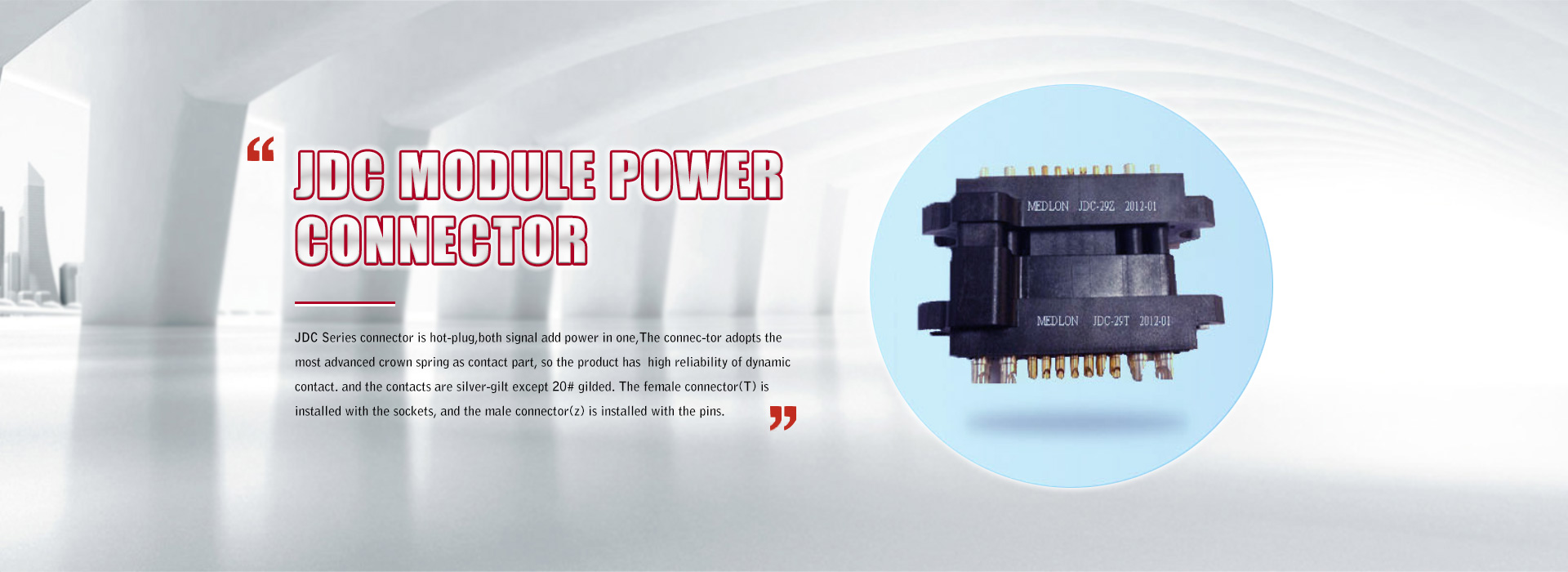

Several factors influence the pricing of JDC power connectors, particularly for manufacturers like Medlon. First and foremost, the materials used in the production process play a significant role. High-quality metals, plastics, and insulating materials are essential for manufacturing reliable connectors that can handle high-power loads. These materials, however, come at a premium.

Next is the complexity of the manufacturing process. Power blade connectors require precision engineering to ensure they meet specific performance requirements. This often involves investing in advanced machinery and skilled labor, which naturally drives up the cost of production. Furthermore, adherence to industry standards and certifications—such as ISO or UL certifications—adds to the overall cost due to the rigorous testing and auditing involved.

Lastly, the scale of production impacts pricing. Medlon benefits from economies of scale in its manufacturing operations, but smaller production runs or highly specialized custom designs will lead to higher unit costs. Additionally, incorporating advanced features such as increased durability, enhanced safety mechanisms, and better heat management will affect the final price.

One of the core differentiators in power blade connector pricing is the level of quality control implemented by the manufacturer. For Medlon, quality assurance is not just a step in the process—it’s embedded in the entire lifecycle of the product. From the initial design to the final inspection, each connector undergoes rigorous testing to ensure it meets or exceeds the required performance metrics.

This commitment to quality directly impacts the pricing of the product. By investing in thorough quality control measures, Medlon ensures that its power blade connectors are less likely to fail in the field, reducing the need for costly repairs or replacements. As a result, customers are willing to pay a premium for connectors that they know will provide long-term reliability and safety.

Medlon’s strict quality control procedures not only ensure that products meet the highest standards but also minimize production inefficiencies. By detecting and addressing issues early in the manufacturing process, Medlon avoids costly rework or product recalls, which could negatively affect pricing.

In the competitive world of power blade connectors, quality control is a crucial factor that influences both the performance and pricing of these components. At Medlon, a dedicated focus on quality assurance helps the company produce power blade connectors that offer reliable performance, durability, and safety. As a result, customers can be confident that they are investing in a high-quality product that will deliver value over the long term. Quality control not only ensures that the product meets stringent industry standards but also reflects in the final pricing, as customers are willing to pay for the peace of mind that comes with superior product performance.