MedlonUploaded:2024-08-17Browse:248

The cost and quality of raw materials play a significant role in the overall pricing of power connectors. As a leading manufacturer of power blade connectors, Medlon understands that the choice of raw materials directly impacts both the performance and cost of the final product. This article explores the relationship between raw material costs and power connector pricing, providing insight into how these factors influence the products we manufacture.

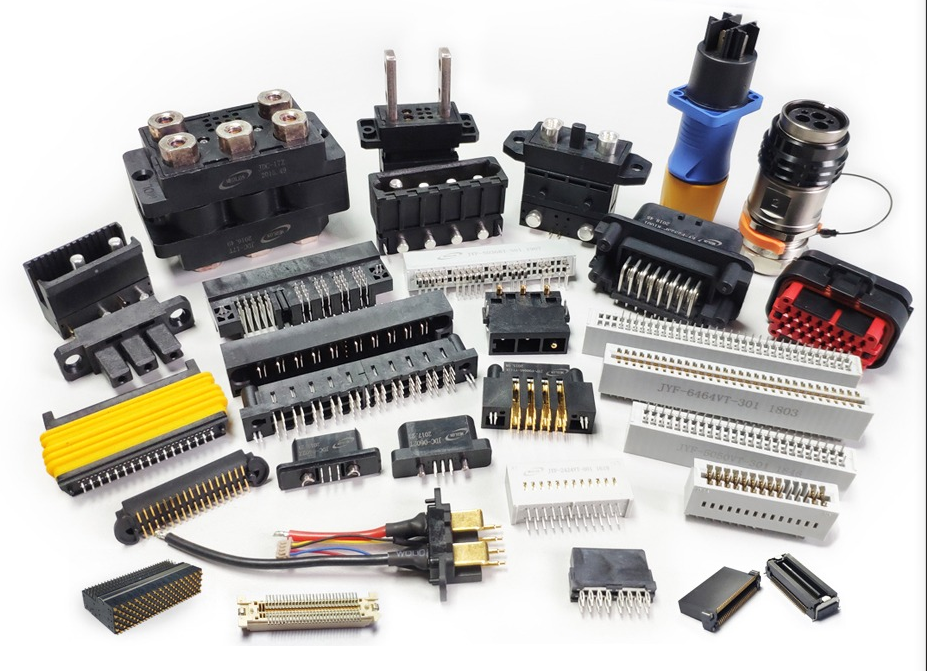

Power connectors are typically made from a variety of materials, each selected for its specific properties that contribute to the connector’s functionality, durability, and performance.

Copper: Copper is the most common material used in the conductive elements of power connectors due to its excellent electrical conductivity and thermal performance. Copper prices fluctuate based on global supply and demand, which can directly impact the cost of power connectors.

Brass: Brass, an alloy of copper and zinc, is often used for connector components that require strength and corrosion resistance. Brass is slightly less conductive than pure copper but offers better mechanical properties, making it suitable for high-durability applications.

Plastics and Insulating Materials: High-quality plastics and polymers are used for the housing and insulation of power connectors. These materials must resist heat, chemicals, and physical stress to ensure long-lasting performance. The type and grade of plastic chosen can significantly affect the cost, with engineering-grade plastics being more expensive but offering superior performance.

Plating Materials: Many connectors are plated with materials like gold, nickel, or tin to enhance conductivity, reduce wear, and prevent corrosion. The choice of plating material and thickness can add to the cost, especially when using precious metals like gold.

Raw material prices are subject to fluctuations due to various factors, including global market conditions, supply chain disruptions, and geopolitical events. These fluctuations can have a direct impact on the pricing of power connectors.

Copper Price Volatility: Copper prices are particularly volatile and are influenced by global demand, especially from industries like construction and electronics. A rise in copper prices can lead to higher manufacturing costs for power connectors, which may be reflected in the final product pricing.

Cost of Precious Metals: The use of precious metals like gold in plating can significantly increase the cost of connectors. As the prices of these metals fluctuate, so too does the cost of producing high-performance connectors. Manufacturers like Medlon must carefully balance the benefits of using such materials against the impact on pricing.

Supply Chain Considerations: Disruptions in the supply chain, such as shortages of certain plastics or metals, can lead to increased raw material costs. These costs are often passed on to the consumer, particularly when the materials in question are critical to the connector's performance.

In power connector manufacturing, there is often a trade-off between the quality of materials used and the cost of the final product. Higher-quality materials generally provide better performance, durability, and reliability but at a higher price.

Performance vs. Cost: Using premium materials such as high-purity copper or gold plating ensures superior electrical performance and longevity, making them ideal for high-demand applications. However, these materials increase the cost of the connectors, which may be passed on to customers who require top-tier performance.

Durability Considerations: For applications where durability and long service life are critical, investing in higher-grade materials like brass or engineering plastics is essential. While these materials are more expensive, they reduce the need for frequent replacements and maintenance, offering cost savings over the long term.

Balancing Cost and Quality: Medlon strives to balance cost and quality by selecting materials that provide the best value for each specific application. This approach ensures that our power connectors meet performance requirements while remaining competitively priced.

Medlon employs several strategies to manage raw material costs effectively, ensuring that we can offer competitive pricing without compromising on quality.

Efficient Sourcing: By sourcing raw materials from reliable suppliers and leveraging bulk purchasing agreements, Medlon can secure materials at favorable prices. This allows us to maintain stable pricing even when market conditions fluctuate.

Material Optimization: Medlon continuously works on optimizing the use of materials in our connector designs, minimizing waste and maximizing efficiency. This not only reduces costs but also supports our commitment to sustainability.

Innovation in Material Use: We invest in research and development to explore alternative materials and innovative manufacturing techniques that can reduce costs while maintaining or enhancing connector performance. This forward-thinking approach helps us stay ahead in a competitive market.

At Medlon, we understand that our customers need reliable, high-performance power connectors at competitive prices. By carefully managing raw material costs and focusing on quality, we deliver products that meet the rigorous demands of industrial, commercial, and consumer applications. Whether you require standard or custom connectors, Medlon offers solutions that balance cost and performance to provide the best value.

In conclusion, the cost of raw materials plays a crucial role in determining the pricing of power connectors. By understanding the impact of material choices and market fluctuations, Medlon is able to offer power connectors that meet the highest standards of quality and reliability while remaining cost-effective. Our commitment to optimizing material use and managing costs ensures that our customers receive the best possible products at competitive prices.