MedlonUploaded:2024-07-01Browse:312

When it comes to efficient and reliable electrical connections, the design of power connectors plays a crucial role. Medlon, a leading power blade connector manufacturer, is at the forefront of innovative connector designs that cater to diverse applications. This article delves into the key differences between power connector pin and socket designs, highlighting Medlon's commitment to quality and performance.

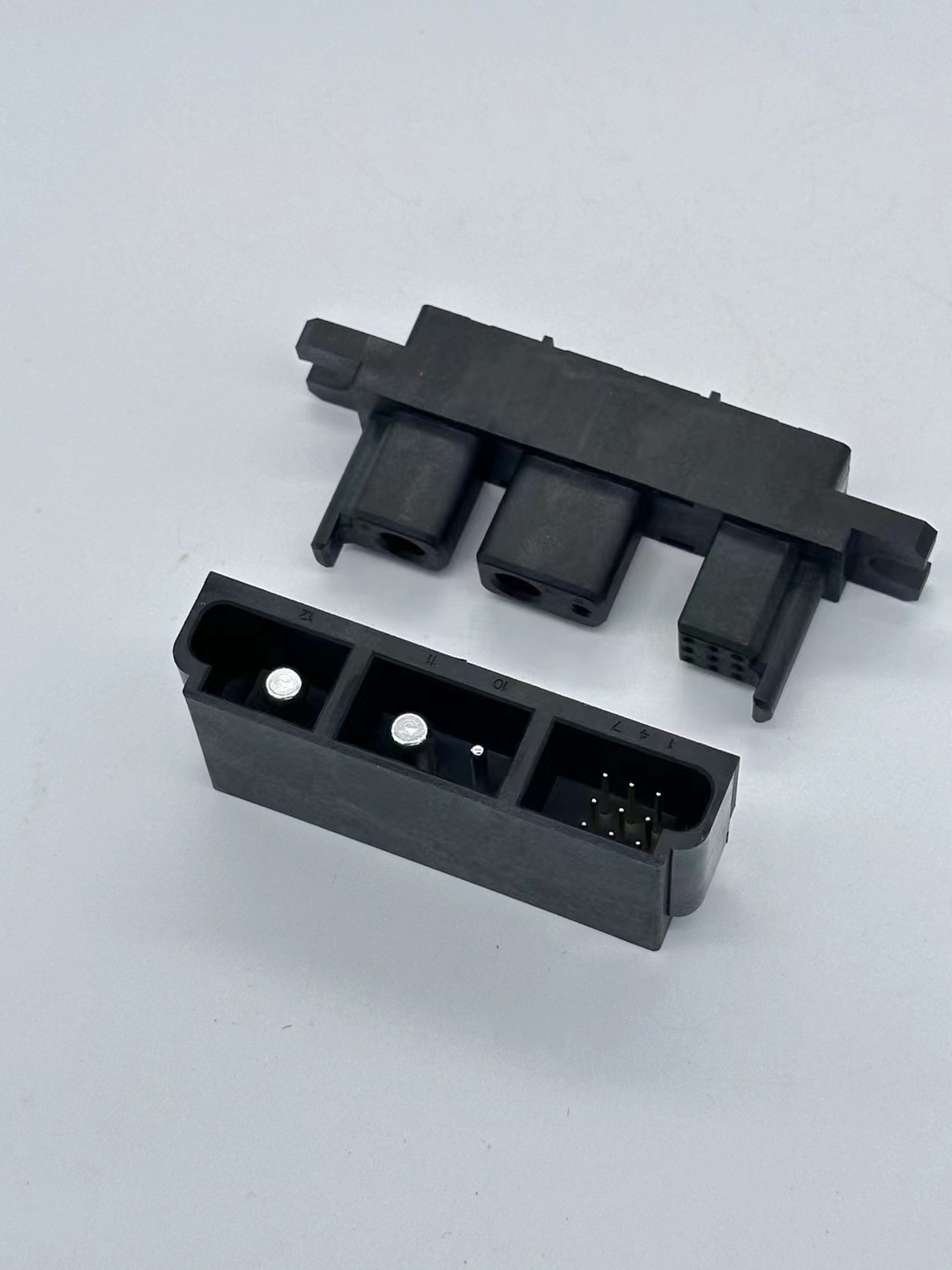

Power connectors are critical components in electrical systems, enabling the safe and efficient transfer of electrical power between devices. They come in various configurations, with pins (male) and sockets (female) being the primary types.

The design of pins and sockets significantly influences the performance, reliability, and ease of use of power connectors. Let's explore the key differences between these two designs.

Pins are typically the protruding elements of a connector. They are designed to fit into corresponding sockets to establish an electrical connection. The structural design of pins can vary, but they are generally robust to ensure a secure and stable connection.

Sockets are designed to receive the pins. They are often equipped with contacts that grip the pins firmly, ensuring a reliable connection. The design of sockets includes considerations for ease of insertion and withdrawal, maintaining contact integrity over numerous cycles.

Pins and sockets must be designed to minimize electrical resistance. High-quality materials and precise manufacturing processes are essential to achieve optimal conductivity. Medlon, as a top-tier manufacturer, employs advanced R&D techniques to enhance the conductivity of their connectors.

Efficient heat dissipation is critical in power connectors. Pins and sockets must be designed to handle high currents without excessive heating. Medlon’s innovative designs incorporate features that improve thermal management, ensuring longevity and reliability.

The mechanical durability of pins and sockets is vital for their longevity. Pins need to withstand insertion and withdrawal forces, while sockets must maintain their grip over time. Medlon’s connectors are engineered with high-quality materials and rigorous testing to ensure exceptional durability.

Proper alignment between pins and sockets is crucial for a reliable connection. Misalignment can lead to connection failure or damage. Medlon's designs incorporate precise tolerances and alignment features to facilitate easy and accurate mating.

Medlon leverages cutting-edge manufacturing techniques to produce high-quality power connectors. Their state-of-the-art factory in China is equipped with advanced machinery and stringent quality control measures, ensuring each connector meets rigorous standards.

As a leading supplier and distributor, Medlon offers comprehensive OEM/ODM services. Their R&D team works closely with clients to design custom connectors that meet specific requirements, providing a significant advantage in terms of cost performance and tailored solutions.

Medlon’s robust supply chain ensures timely delivery of connectors to customers worldwide. As a trusted wholesaler and agent, they maintain a reliable inventory and efficient distribution network, catering to the diverse needs of their clients.

The design of power connector pins and sockets is fundamental to the performance and reliability of electrical connections. Medlon, a premier power blade connector manufacturer, excels in producing high-quality connectors through innovative designs and advanced manufacturing processes. Whether for OEM/ODM projects or standard applications, Medlon’s connectors offer unmatched durability, conductivity, and mechanical performance, making them a preferred choice for customers around the globe.